What Is a Self Centering Vise and Why It Matters in Modern CNC Machining

A self centering vise is a precision workholding device designed to clamp parts symmetrically from both sides, automatically positioning the workpiece at the center of the machine axis. Unlike traditional vises that push material from one direction, a self-centering vise applies balanced clamping force, improving repeatability, accuracy, and machining efficiency.

As CNC machining moves toward automation, 5-axis setups, and high-mix low-volume production, more engineers and manufacturers search for self centering vise solutions to reduce setup time and eliminate alignment errors.

Typical search intent behind this keyword includes:

-

Understanding how a self-centering vision works

-

Comparing it with standard machine vises

-

Learning when to use a self centering vise in CNC production

-

Finding best practices for precision machining setups

How a Self Centering Vise Works

A self centering vise uses synchronized jaws that move inward simultaneously when clamping. This mechanism ensures the workpiece remains aligned to the centerline without manual adjustment.

H3: Key Structural Components

-

Dual synchronized jaws – move evenly toward the center

-

Precision lead screw or wedge system – ensures balanced force

-

Rigid base body – minimizes vibration during machining

-

Repeatable locating surfaces – ideal for automated setups

When the operator tightens the vise, both jaws close at the same rate, maintaining perfect centering. This makes a self centering vise especially valuable in high-precision CNC applications.

Self Centering Vise vs Traditional Machine Vise

One of the most common questions users ask is how a self centering vise compares to a standard vise. The difference lies mainly in setup speed and repeatability.

| Feature | Self Centering Vise | Traditional Machine Vise |

| Alignment | Automatic centering | Manual alignment required |

| Setup Time | Very fast | Moderate to slow |

| Repeatability | Extremely high | Depends on operator |

| Multi-side machining | Excellent | Limited |

| Ideal for automation | Yes | Not always |

Because the self centering vise eliminates manual positioning, it reduces human error and improves machining consistency.

Advantages of Using a Self Centering Vise in CNC Machining

1. Improved Accuracy and Repeatability

The most significant benefit of a self centering vise is symmetrical clamping. By distributing force evenly, it reduces distortion and keeps the part precisely aligned with the spindle axis.

Key benefits include:

-

Reduced runout during machining

-

Better dimensional stability

-

Consistent part positioning across batches

2. Faster Setup and Reduced Downtime

Manufacturers searching for “self centering vise setup efficiency” often want to shorten machine idle time. Since the workpiece centers automatically:

-

Operators spend less time indicating parts

-

Setup procedures become standardized

-

Production changeovers are faster

3. Ideal for 5-Axis and Multi-Side Machining

A self centering vise allows better access to multiple faces of the workpiece. This is especially useful in:

-

Aerospace components

-

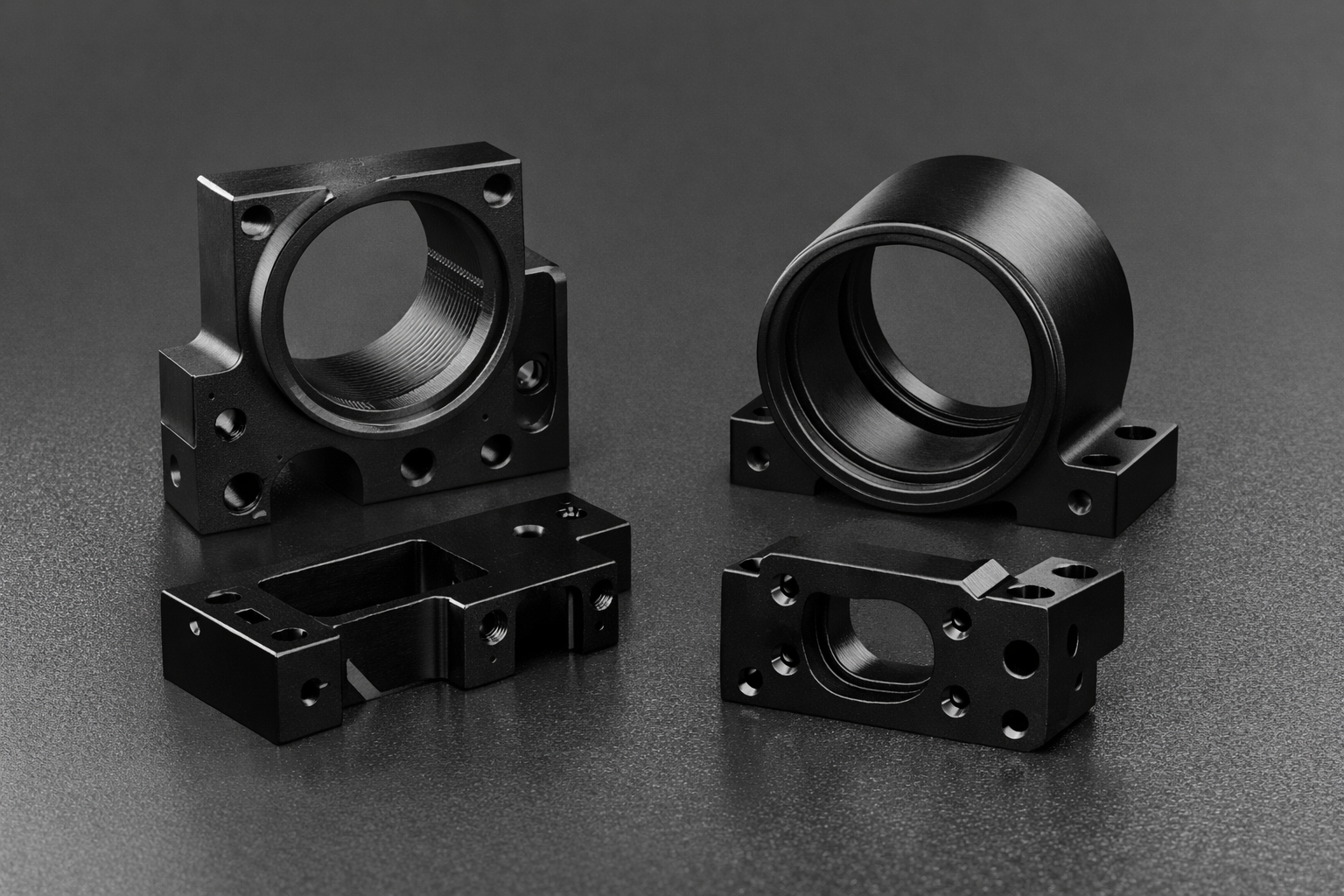

Optical housings

-

Precision aluminum parts

-

Medical device machining

Common Applications of Self Centering Vise Systems

The versatility of the self centering vise makes it suitable across many industries.

Automotive and Robotics

High-volume machining environments use self centering vises to clamp gears, housings, and robotic structure parts with consistent accuracy.

Medical and Optical Components

Precision industries require stable clamping without deformation. A self centering vise provides:

-

Balanced pressure

-

Reduced surface damage

-

High repeatability for tight tolerances

General Industrial Machining

Manufacturers producing aluminum or stainless steel parts benefit from reduced setup variation and improved workflow efficiency.

Types of Self Centering Vise Designs

Not all self centering vises are the same. Understanding design variations helps users choose the right solution.

Mechanical Self Centering Vise

-

Uses screw-driven synchronization

-

Reliable and cost-effective

-

Ideal for manual CNC setups

Hydraulic Self Centering Vise

-

Provides consistent clamping force

-

Suitable for automated production lines

-

Reduces operator fatigue

Zero-Point Compatible Self Centering Vise

Many modern systems integrate with zero-point clamping systems, allowing quick mounting and repeatable positioning on the machine table.

How to Choose the Right Self Centering Vise

Engineers often search for guidance on selecting the best self centering vise for their application.

Key Selection Factors

-

Clamping Force Requirement

-

Workpiece size and material

-

Machine table compatibility

-

Repeatability requirements

-

Jaw stroke and opening range

Practical Selection Table

| Application | Recommended Self Centering Vise Type |

| 5-axis machining | Low-profile self centering vise |

| Aluminum housings | Precision mechanical vise |

| Steel parts | High-force hydraulic vise |

| Automated production | Zero-point compatible vise |

Best Practices for Using a Self Centering Vise

Even the best self centering vise requires correct usage to achieve optimal performance.

Setup Tips

-

Clean the locating surfaces before clamping

-

Use torque control for consistent force

-

Select proper soft jaws for irregular parts

Maintenance Tips

-

Lubricate the screw or wedge mechanism regularly

-

Inspect jaw alignment periodically

-

Avoid over-tightening to prevent deformation

By following these practices, manufacturers can extend the life of their self centering vise while maintaining machining accuracy.

Common Problems and Solutions

Problem: Workpiece Shifting During Machining

Possible Causes:

-

Insufficient clamping force

-

Worn jaws

-

Improper jaw design

Solution: Upgrade to a higher-force self centering vise or customize soft jaws.

Problem: Surface Marks on Parts

Balanced clamping reduces this issue, but using protective jaw inserts can further improve results.

Future Trends in Self Centering Vise Technology

The demand for automated machining is driving innovation in self centering vise design.

Emerging trends include:

-

Integration with smart sensors

-

Modular jaw systems

-

Lightweight aerospace-grade materials

-

Compatibility with robotic loading systems

As Industry 4.0 evolves, the self centering vise will become a core component of smart CNC manufacturing.

Final Thoughts: Why a Self Centering Vise Is a Smart Investment

For manufacturers focused on precision, efficiency, and repeatability, a self centering vise offers clear advantages over traditional clamping solutions. It reduces setup time, improves machining accuracy, and supports complex multi-axis operations.

Whether you produce optical components, robotic structures, medical devices, or aluminum housings, integrating a self centering vise into your workflow can significantly enhance productivity.

By understanding how a self centering vise works, how to choose the right design, and how to apply best practices, CNC users can unlock higher machining performance and consistent quality across production runs.

공유하다:

XY-GLOBAL, SPIE Photonics West 2026 참가 | 정밀 제조