📺 Project Video:

Project Background

This project was developed for a U.S.-based manufacturer of high-performance LED lighting systems used in architectural and commercial environments.

In these applications, two things are non-negotiable:

-

Structural stability

-

Appearance consistency

Even internal structural parts must meet strict dimensional and visual standards to ensure reliable assembly and long service life.

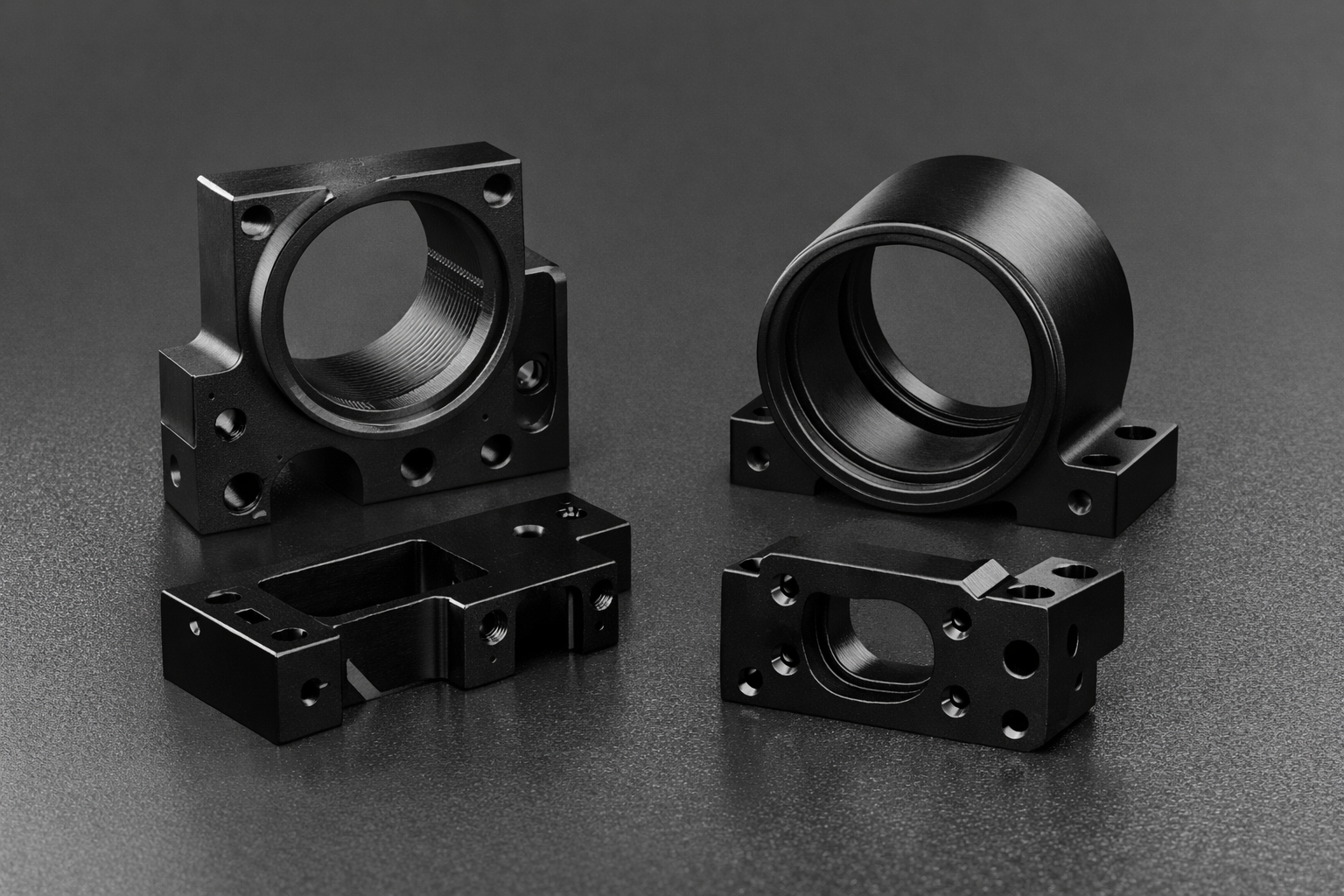

The Component We Supplied

We supplied a precision injection molded structural part used inside the LED lighting assembly for support and positioning.

Although it is not an external decorative part, the customer required:

✅ Stable dimensions

✅ Smooth assembly fit

✅ Clean molded surface

✅ No visible cosmetic defects

This placed high demands on both mold design and injection molding process control.

Material Selection: Why PC Injection Molding

The part is produced using PC injection molding (polycarbonate) due to its balanced performance:

-

High mechanical strength

-

Good heat resistance

-

Strong dimensional stability

-

Suitable for long-term structural support

For LED system components exposed to heat and continuous operation, PC material provides reliable performance over time.

Customer Requirements — Clear And Strict

From the beginning, the customer defined detailed acceptance standards for the molded LED structural parts:

Dimensional Requirements

-

Stable critical dimensions

-

Controlled tolerance for assembly features

-

Consistent repeatability between batches

Appearance Requirements

-

No flow lines

-

No sink marks

-

No color variation

-

Uniform surface quality

Production Requirements

-

Predictable delivery schedule

-

Stable process window

-

Low defect rate

This was not just a molding job — it was a process stability challenge.

The Core Challenge

The main difficulty was balancing:

Structural performance vs. cosmetic consistency

In PC injection molding, improving strength and fill behavior can sometimes increase the risk of:

-

Flow marks

-

Surface variation

-

Internal stress

-

Visual defects

That meant early process strategy was critical.

How We Solved It

We addressed risks early through a structured injection molding development approach:

✔ Early Mold Trials

Multiple mold trials were conducted to validate filling behavior and gate performance.

✔ Process Optimization

We optimized:

-

Injection speed profile

-

Melt temperature window

-

Packing pressure control

-

Cooling balance

✔ Critical Feature Verification

Key structural and assembly features were measured and verified during early runs to prevent later-stage risk.

This reduced adjustment cycles during mass production.

Production Results

After process tuning and validation, the final injection molded parts achieved:

✅ Stable dimensions

✅ Reliable assembly fit

✅ Clean and consistent appearance

✅ No visible molding defects

✅ Batch-to-batch consistency

Both functional and cosmetic requirements were met.

Customer feedback was positive, and the project progressed into continued cooperation.

Why This Injection Molding Project Matters

This case shows that successful precision injection molding for LED structural components is not only about making parts — it is about controlling the process.

When appearance, tolerance, and reliability must exist together, early engineering involvement and process discipline make the difference.

Need Custom Injection Molded Structural Parts?

We support customers with:

-

PC injection molding

-

Precision structural plastic parts

-

Appearance-controlled molded components

-

LED and electronics structural parts

-

Custom injection molding based on drawings

📩 If you have a similar project, feel free to send us your drawings or specifications.

Our engineering team will review and support your production plan.

Share:

A Story of Integrity Behind a Small Sample

Engineering Services: Capability & Production Control for Precision Manufacturing